TM

Gebouwd voor de toekomst van automatisering

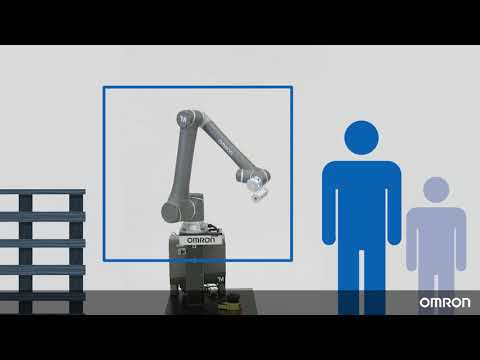

- Ontworpen om een veilige en harmonieuze werkomgeving voor samenwerking tussen mens en machine te bevorderen.

- 31 veiligheidsfuncties, alle gecertificeerd volgens ISO 13849-1, cat. 3, PLd.

- Volledig conform ISO 10218-1.

- Gebruiksvriendelijke grafische programmeeromgeving voor snel opstarten en bedrijf.

- Ingebouwde vision-gebaseerde robotbesturing maakt visuele servobesturing, inspectie en metingen mogelijk.

- Optionele camera en landmark maken een werkelijk flexibele, snelle omschakeling mogelijk.

- De mogelijkheid van integratie met mobiele robots maakt toepassingen voor volledig autonome belading van machines en logistieke handling mogelijk.

- Fieldbus models inclusief EtherNet/IP en Profinet.

-

Meet our collaborative robot

For over 85 years, Omron has helped perfect the art of machines that help humans. Now, we introduce the machines specifically built to work with people - meet the Omron TM Collaborative Robot Series!

02:23

Meet our collaborative robot

For over 85 years, Omron has helped perfect the art of machines that help humans. Now, we introduce the machines specifically built to work with people - meet the Omron TM Collaborative Robot Series!De collaboratieve robot

Omron TM12 cobot automates booklet feeding for Kraus Maschinenbau

Cobots streamline processes in medtech and packaging industry

Kenmerken

Snellere installatie met ingebouwde vision

-

Meet our collaborative robot

For over 85 years, Omron has helped perfect the art of machines that help humans. Now, we introduce the machines specifically built to work with people - meet the Omron TM Collaborative Robot Series!

02:23

Snel opstarten en overschakelen

Veiligheid bij samenwerkingstoepassingen

Cobot Safety Specialistenartikel

Cobot and flexible production - Future-proofing SMEs?

Many countries in Europe, such as the UK and Germany are likely to experience serious labour shortages over the coming decade, especially in relation to technical specialists. At the same time, product lifecycles are becoming shorter. Despite this, small and medium-sized enterprises (SMEs) might be reluctant to invest in additional automation. However, collaborative robots (cobots) are easy to set up and offer a quick and cost-effective solution. They can increase the flexibility, quality and speed of production and enable companies to respond rapidly to changing market conditions. Omron’s TM series of cobots are a good example of this versatility.

Modellen

TM5S

- Bereik (mm): 900

- Maximale payload (kg): 5

- Maximale snelheid (m/s): 1,4

TM7S

- Bereik (mm): 700

- Maximale payload (kg): 7

- Maximale snelheid (m/s): 1,1

TM12S

- Bereik (mm): 1300

- Maximale payload (kg): 12

- Maximale snelheid (m/s): 1,3

TM14S

- Bereik (mm): 1100

- Maximale payload (kg): 14

- Maximale snelheid (m/s): 1,1

TM 5 – 700

- Bereik (mm): 700

- Maximale payload (kg): 6

- Maximale snelheid (m/s): 1,1

TM 5 – 900

- Bereik (mm): 900

- Maximale payload (kg): 4

- Maximale snelheid (m/s): 1,4

TM12

- Bereik (mm): 1300

- Maximale payload (kg): 12

- Maximale snelheid (m/s): 1,3

TM14

- Bereik (mm): 1100

- Maximale payload (kg): 14

- Maximale snelheid (m/s): 1,1

TM16

- Bereik (mm): 900

- Maximale payload (kg): 16

- Maximale snelheid (m/s): 1,1

TM20

- Bereik (mm): 1300

- Maximale payload (kg): 20

- Maximale snelheid (m/s): 1,3

Specificaties & bestelinfo

| Product | Hardware version | Payload | Reach | PROFINET communication | EtherNet/IP communication | Vision | Power supply type | SEMI S2 certified | Food grade grease | SIL according to IEC 61508 | Performance level according to EN ISO 13849-1 | Cable length | Beschrijving | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

3.2 | 6 kg | 700 mm | No | No | Yes | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5-700, HW3.2 |

|

|

|

3.2 | 6 kg | 700 mm | No | No | Yes | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5-700, 12 m cable, HW3.2 |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | Yes | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5-700, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | Yes | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5-700, 12 m cable, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 6 kg | 700 mm | No | No | Yes | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5-700, HW3.2, Food Grade Grease |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | Yes | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5-700, HW3.2, PROFINET & EtherNet/IP, Food Grade Grease |

|

|

|

3.2 | 4 kg | 900 mm | No | No | Yes | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5-900, HW3.2 |

|

|

|

3.2 | 4 kg | 900 mm | No | No | Yes | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5-900, 12 m cable, HW3.2 |

|

|

|

3.2 | 4 kg | 900 mm | Yes | Yes | Yes | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5-900, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 4 kg | 900 mm | Yes | Yes | Yes | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5-900, 12 m cable, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 4 kg | 900 mm | No | No | Yes | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5-900, HW3.2, Food Grade Grease |

|

|

|

3.2 | 4 kg | 900 mm | Yes | Yes | Yes | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5-900, HW3.2, PROFINET & EtherNet/IP, Food Grade Grease |

|

|

|

3.2 | 6 kg | 700 mm | No | No | No | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5X-700 (model without camera), HW3.2 |

|

|

|

3.2 | 6 kg | 700 mm | No | No | No | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5X-700 (model without camera), 12 m cable, HW3.2 |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | No | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5X-700 (model without camera), HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | No | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5X-700 (model without camera), 12 m cable, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 6 kg | 700 mm | No | No | No | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5X-700 (model without camera), HW3.2, Food Grade Grease |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | No | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5X-700 (model without camera), HW3.2, PROFINET & EtherNet/IP, Food Grade Grease |

|

|

|

3.2 | 4 kg | 900 mm | No | No | No | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5X-900 (model without camera), HW3.2 |

|

|

|

3.2 | 4 kg | 900 mm | No | No | No | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5X-900 (model without camera), 12 m cable, HW3.2 |

|

Wij staan klaar om u te helpen

Hebt u een vraag? Onze specialisten staan klaar om u bij elke stap te helpen.

Neem contact met mij op TM

Dank u wel voor het insturen van uw verzoek. Wij informeren u zo snel als mogelijk.

Wij ondervinden technische problemen. Uw formulierinzending is niet gelukt. Onze verontschuldigingen hiervoor, probeer het later nog een keer. Details: [details]

Offerte voor TM

Met dit formulier kunt u een prijsaanvraag doen voor de producten van uw keuze. Vul alstublieft alle velden in die gemarkeerd zijn met *. Uw persoonlijke gegevens behandelen wij uiteraard volstrekt vertrouwelijk.

Dank u wel voor uw aanvraag. Wij zenden u de gewenste informatie zo snel als mogelijk.

Wij ondervinden technische problemen. Uw formulierinzending is niet gelukt. Onze verontschuldigingen hiervoor, probeer het later nog een keer. Details: [details]

Klantverhalen

Cobots give gear manufacturer a competitive production edge

Danish gear manufacturer, Fischer Gears, has boosted the competitiveness of its production process - especially on larger series – by installing two OMRON TM robots. The collaborative robots (cobots) free experienced employees to focus on more value-adding tasks.

Innovatieve cobot-toepassing verbetert veiligheid bij Leica Geosystems

De collaboratieve robot automatiseert de verwerking van trays en verbetert de veiligheid en ergonomie in een gevaarlijke werkomgeving.

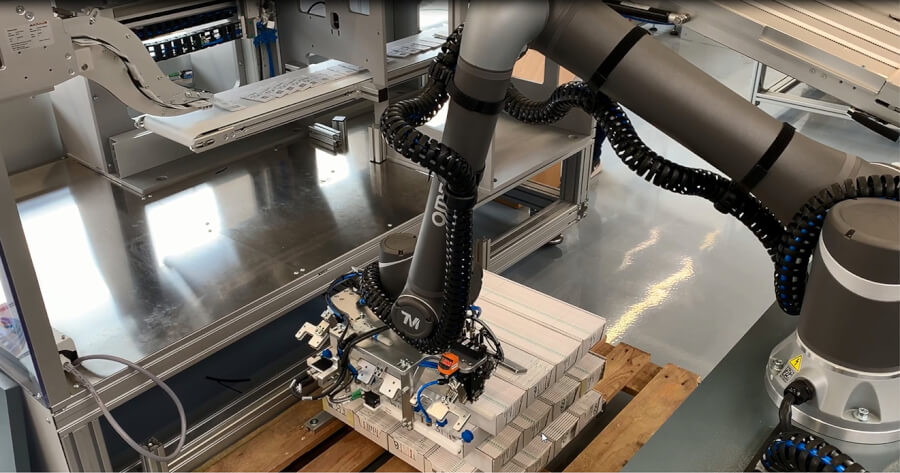

Collaboratieve robots verbeteren de productiviteit bij CLECA

Palletiseerproces geautomatiseerd met Omron TM12-cobots

Palletiseeroplossing van Reitec voldoet aan de behoeften van FMCG-klanten

OMRON en Reitec bundelen hun krachten om de nieuwe cobotpalletiseeroplossing RC-1 te creëren

Flexibele cobotpalletiser van Reeco Automation

60% kleinere footprint en tot 50% lagere kosten in vergelijking met conventionele robotpalletisers

Traceerbaarheid 4.0 door gestroomlijnde etikettering van verpakkingen met cobots

Een collaborative robot voert een intelligente etikettering uit op verschillende productformaten, waardoor de uitvaltijd als gevolg van formaatveranderingen met wel 70% wordt verminderd. Deze oplossing is ontwikkeld door Bluengineering voor Gruppo Romani in Italië.

Cisel garandeert traceerbaarheid, veiligheid en kwaliteit door printplaten te testen met een cobot

Cisel is een Italiaans bedrijf dat gespecialiseerd is in het ontwerpen en produceren van flexibele printplaten (PCB's) voor de auto-, civieltechnische en productiesector. Het bedrijf koos onlangs voor een TM5-cobot (collaborative robot) van OMRON om het elektrisch testen van platen die worden gebruikt in het stuurbekrachtigingssysteem van een toonaangevende autofabrikant te automatiseren.

Een cobot zorgt voor een nauwkeurige montage van magneten voor de aftappluggen van LITMAT

Collaborative robots (cobots) worden steeds uitgebreider gebruikt in een reeks verschillende bedrijfstakken en in een breed scala aan toepassingen. Ze kunnen een aanzienlijk verschil maken voor de efficiëntie en productiviteit van de productiecyclus. Eén bedrijf dat van dergelijke voordelen profiteert, is LITMAT SpA.

Unika neemt principebeslissing om de kwaliteit naar een hoger niveau te tillen

OMRON TM-cobots met geïntegreerd vision-systeem voorkomen menselijke fouten en verhogen de productie-efficiëntie.

Applicaties

Oplossingen

OMRON Mobile Manipulator

De unieke hybride conceptoplossing met cobot en mobiele robot van OMRON

Cobot Palletiser Oplossing

OMRON Sysmac PLC op ''FB'' gebaseerde software

Tutorialvideo's

-

Omron Collaborative can draw!

Omron Collaborative Robot can be used for a variety of purposes and numerous applications especially machine tending, loading and unloading, assembling, gluing, testing, and soldering! On this video you can see just one of them, drawing Omron’s logo with a pen on the blackboard! Just amazing Omron Collaborative Robots can do.

00:31

Omron Collaborative can draw!

Omron Collaborative Robot can be used for a variety of purposes and numerous applications especially machine tending, loading and unloading, assembling, gluing, testing, and soldering! On this video you can see just one of them, drawing Omron’s logo with a pen on the blackboard! Just amazing Omron Collaborative Robots can do.

-

Omron Collaborative Robots Tutorial 1 - Unboxing and Initial Set Up

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will show you how to unbox the Cobot and do the initial set up. There are several Cobot in the TM Series depending on your needs. Here we will be using the TM5 – 700 models to explain the common features.

06:34

Omron Collaborative Robots Tutorial 1 - Unboxing and Initial Set Up

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will show you how to unbox the Cobot and do the initial set up. There are several Cobot in the TM Series depending on your needs. Here we will be using the TM5 – 700 models to explain the common features.

-

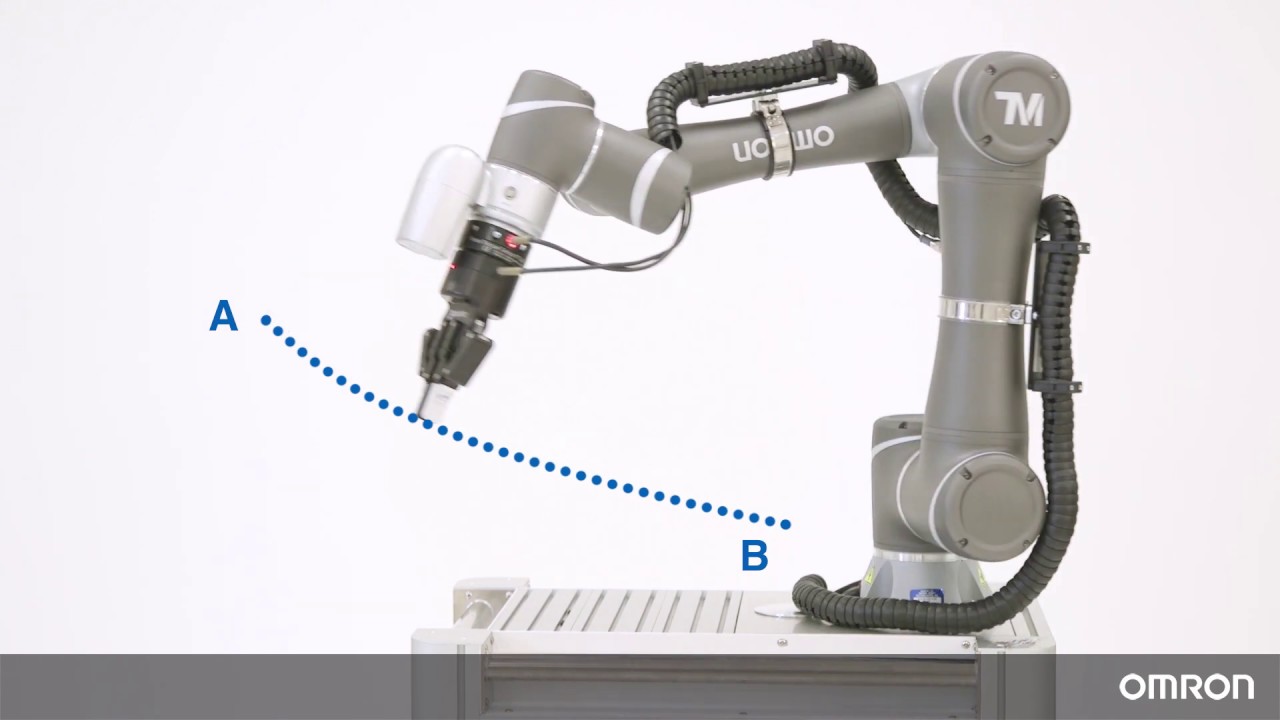

Omron Collaborative Robots Tutorial 2 – Programming the Basic Motions

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we would like to show you the basics of how to make the Cobot move.

06:40

Omron Collaborative Robots Tutorial 2 – Programming the Basic Motions

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we would like to show you the basics of how to make the Cobot move.

-

Omron Collaborative Robots Tutorial 3 – How to Program Using Flow Chart Software

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, you can learn how to use the software, called “TMflow,” to program the Cobots. TMflow has an intuitive user interface that allows you to easily create a program using flowcharts.

05:23

Omron Collaborative Robots Tutorial 3 – How to Program Using Flow Chart Software

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, you can learn how to use the software, called “TMflow,” to program the Cobots. TMflow has an intuitive user interface that allows you to easily create a program using flowcharts.

-

Omron Collaborative Robots Tutorial 4 – How to Attach a Gripper to the Cobot

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we will show you how to use grippers with your Cobot.

04:37

Omron Collaborative Robots Tutorial 4 – How to Attach a Gripper to the Cobot

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we will show you how to use grippers with your Cobot.

-

Omron Collaborative Robots Tutorial 5 – Vision Calibration and Vision Node

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we will show you how to start using the built-in camera and the integrated vision system for your applications. One of the biggest advantages of this Cobot is that you can rapidly create an application in which you want the Cobot to see and recognize the object that it is working on. You do not need additional lens nor lights.

05:13

Omron Collaborative Robots Tutorial 5 – Vision Calibration and Vision Node

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we will show you how to start using the built-in camera and the integrated vision system for your applications. One of the biggest advantages of this Cobot is that you can rapidly create an application in which you want the Cobot to see and recognize the object that it is working on. You do not need additional lens nor lights.

-

Omron Collaborative Robots Tutorial 6 – Pick and Place Using Vision

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we finished the vision calibration and explored some of the vision tasks. So now we are ready to start creating an application that utilizes the camera and the vision system. We will pick up a cylinder from this hole and place it here.

06:46

Omron Collaborative Robots Tutorial 6 – Pick and Place Using Vision

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we finished the vision calibration and explored some of the vision tasks. So now we are ready to start creating an application that utilizes the camera and the vision system. We will pick up a cylinder from this hole and place it here.

-

Omron Collaborative Robots Tutorial 7 – Updating TMFlow software

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will show how to update the TMFlow software. We constantly have software updates, so make sure you update Collaborative Robots software so that you can utilize the newest features.

04:49

Omron Collaborative Robots Tutorial 7 – Updating TMFlow software

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will show how to update the TMFlow software. We constantly have software updates, so make sure you update Collaborative Robots software so that you can utilize the newest features.

-

Omron Collaborative Robots Tutorial 8 – Communication via ModBus

Meet the Omron Collaborative Robot Series to assist your automation needs. The Omron Collaborative Robots is capable of different types of communications. On this video we will focus on using ModBus TCP communication in TMFlow software.

07:15

Omron Collaborative Robots Tutorial 8 – Communication via ModBus

Meet the Omron Collaborative Robot Series to assist your automation needs. The Omron Collaborative Robots is capable of different types of communications. On this video we will focus on using ModBus TCP communication in TMFlow software.

-

Omron Collaborative Robots Tutorial 9 – Advanced Motion Methods

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will discuss the different types of advanced motions that Omron’s Collaborative Robots can achieve. We will focus on some of the different types of motions that our Cobots can use to fit in your applications.

04:32

Omron Collaborative Robots Tutorial 9 – Advanced Motion Methods

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will discuss the different types of advanced motions that Omron’s Collaborative Robots can achieve. We will focus on some of the different types of motions that our Cobots can use to fit in your applications.

-

Collaborative Robot Safety Tutorial - Video 1

Watch this safety video to learn about Omron's Collaborative Robot safety features. Safety Standards & Safety Functions, Emergency Stop & Protective Stop and Safety Output Functions will be discussed. Note: this video is intended to be an introductory guide, for futher important information on safety please refer to the other available safety documentation.

05:50

Collaborative Robot Safety Tutorial - Video 1

Watch this safety video to learn about Omron's Collaborative Robot safety features. Safety Standards & Safety Functions, Emergency Stop & Protective Stop and Safety Output Functions will be discussed. Note: this video is intended to be an introductory guide, for futher important information on safety please refer to the other available safety documentation.

-

Collaborative Robot Safety Tutorial - Video 2

Watch this second part safety video to learn even more about Omron's Collaborative Robot safety features. Intuitive Safety Parameter Setting, Cartesian Safety Limit and Omron Risk Assessment Service will be discussed. Note: this video is intended to be an introductory guide, for futher important information on safety please refer to the other available safety documentation.

06:55

Collaborative Robot Safety Tutorial - Video 2

Watch this second part safety video to learn even more about Omron's Collaborative Robot safety features. Intuitive Safety Parameter Setting, Cartesian Safety Limit and Omron Risk Assessment Service will be discussed. Note: this video is intended to be an introductory guide, for futher important information on safety please refer to the other available safety documentation.Downloaden

Services

Hulp nodig?

Wij zijn er om u te helpen! Neem contact met ons op en onze specialisten helpen u bij het vinden van de beste oplossing voor uw bedrijf.

Neem contact met mij op TM

Dank u wel voor het insturen van uw verzoek. Wij informeren u zo snel als mogelijk.

Wij ondervinden technische problemen. Uw formulierinzending is niet gelukt. Onze verontschuldigingen hiervoor, probeer het later nog een keer. Details: [details]

Offerte voor TM

Met dit formulier kunt u een prijsaanvraag doen voor de producten van uw keuze. Vul alstublieft alle velden in die gemarkeerd zijn met *. Uw persoonlijke gegevens behandelen wij uiteraard volstrekt vertrouwelijk.

Dank u wel voor uw aanvraag. Wij zenden u de gewenste informatie zo snel als mogelijk.

Wij ondervinden technische problemen. Uw formulierinzending is niet gelukt. Onze verontschuldigingen hiervoor, probeer het later nog een keer. Details: [details]