E5_D/H

Nouvelle génération de contrôleurs

Les E5_D/H sont des contrôleurs nouvelle génération, conçus pour assurer un contrôle de température optimal et automatique sans intervention humaine. Tous les réglages que les techniciens devaient réaliser sur le terrain sont désormais automatisés grâce à l'intelligence artificielle (IA).

- La « technologie de commande adaptative » détecte automatiquement les changements du processus contrôlé et adapte le PID en conséquence.

- Fonctions spécialisées pour les machines de conditionnement et les extrudeuses refroidies à l'eau

- Grand écran LCD blanc à haut niveau de contraste et affichage clair, offrant une visibilité à plus grande distance et un angle de vue plus large

- Fonction de commutation de banque (groupe PID), pour des modifications rapides des paramètres de l'appareil (E5_D-H uniquement)

- 5 fonctions de pré-amplification pour supprimer les fluctuations de température prévisibles (E5_D-H uniquement)

Caractéristiques et références

| Produit | Size | Functions | Number of control loops | Temperature input type | Linear analog input type | Temperature range | Features | Number of event inputs | Number of alarm outputs | Supply voltage AC | Supply voltage DC | Control output | Communication port(s) | Terminal type | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 100-240 V | Linear current | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Linear current output, 2 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 20.4-26.4 V | 20.4-26.4 V | Linear current | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Linear current output,, 2 Alarm outputs, 24 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 100-240 V | Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Voltage pulse output, 2 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 20.4-26.4 V | 20.4-26.4 V | Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Voltage pulse output, 2 Alarm outputs, 24 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 100-240 V | Relay | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Relay output, 2 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 20.4-26.4 V | 20.4-26.4 V | Relay | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Relay output, 2 Alarm outputs, 24 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

|

|

|

1/16 DIN (48 x 48 mm) | HB/HS alarm for 1-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 100-240 V | Voltage pulse | Serial RS-485 | Push-in | Temperature controller, PRO, 1/16 DIN (48 x 48 mm), 1 x 12 VDC pulse OUT, 2 AUX, RS-485, Ht. Burnout SSR fail., 100 to 240 VAC |

|

||

|

|

1/16 DIN (48 x 48 mm) | HB/HS alarm for 1-phase heaters, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 20.4-26.4 V | 20.4-26.4 V | Voltage pulse | Serial RS-485 | Screw | Temp. controller, PRO, 1/16 DIN (48 x 48 mm), 1 x 12 VDC pulse OUT, 2 AUX,RS-485, Ht. Burnout SSR fail., 24 VAC/DC |

|

|

|

|

1/16 DIN (48 x 48 mm) | HB/HS alarm for 1-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 20.4-26.4 V | 20.4-26.4 V | Voltage pulse | Serial RS-485 | Push-in | Temperature controller, PRO, 1/16 DIN (48 x 48 mm), 1 x 12 VDC pulse OUT, 2 AUX,RS-485, Ht. Burnout SSR fail., 24 VAC/DC |

|

|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 100-240 V | Relay | Screw | Temp. controller, PRO, 1/16 DIN (48 x 48 mm), 1 x Rel. OUT, 2 AUX, 100 to 240 VAC |

|

|||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 20.4-26.4 V | 20.4-26.4 V | Relay | Screw | Temp. controller, PRO, 1/16 DIN (48 x 48 mm), 1 x Rel. OUT, 2 AUX, 24 VAC/DC |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 20.4-26.4 V | 20.4-26.4 V | Relay | Push-in | Temperature controller, PRO, 1/16 DIN (48 x 48 mm), 1 x Rel. OUT, 2 AUX, 24 VAC/DC |

|

||

|

|

1/8 DIN (96 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | 2 Linear current | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Linear current outputs, 4 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, Transfer output, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | 2 Linear current | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Linear current outputs, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, Transfer output, Remote SP |

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | Linear current, Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, Linear current output, Voltage pulse output, 4 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | Linear current, Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, Linear current output, Voltage pulse output, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | 2 Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Voltage pulse outputs, 4 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | 2 Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Voltage pulse outputs, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | Relay, Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, Voltage pulse output, Relay output, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | Relay, Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, Voltage pulse output, Relay output, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

Besoin d'aide ?

Nous sommes là pour vous aider ! Contactez-nous et nos spécialistes vous aideront à trouver la meilleure solution pour votre entreprise.

Contactez-moi E5_D/H

Merci de votre demande. Nous reviendrons vers vous dès que possible.

Nous rencontrons des problèmes techniques. Votre demande ne peut être traitée. Veuillez nous excuser et ré-essayer plus tard. Détails :

Devis pour E5_D/H

Vous pouvez utiliser ce formulaire pour demander un devis sur le produit de votre choix. Merci de compléter tous les champs *. Les informations sont traitées de manière confidentielle.

Merci de votre demande. Nous vous enverrons l'information demandée au plus tôt.

Nous rencontrons des problèmes techniques. Votre demande ne peut être traitée. Veuillez nous excuser et ré-essayer plus tard. Détails :

Fonctions

Algorithme de contrôle adaptatif

-

E5_D Temperature contoller: Adaptive control algorithm

With standard temperature controllers, not only do you need a long time to define initial start-up PID settings, but it is also really challenging to make the optimal adjustments without having many years of experience in this area. That’s why Omron developed the E5_D Series with “adaptive control technology”. This automatically detects changes in the process under control and adapts the PID accordingly.

01:26

Les régulateurs de température standard imposent non seulement des temps de définition des paramètres de PID de démarrage initial très longs, mais il faut, en outre, beaucoup d'expérience pour réaliser des réglages optimaux. C'est pourquoi, dans la conception de sa série E5_D, Omron a fait appel à la « technologie de contrôle adaptatif » qui détecte automatiquement les changements du processus contrôlé et adapte le PID en conséquence.

Vérification de la température de scellage des machines d'emballage

-

E5_D TC: Perfect sealing temperature control for packaging machines (1)

On a conventional sealing machine temperature sensors can often be located too far away from the sealing surface of the heating bar. This causes a difference between the temperature of the sealing surface and the temperature that was actually being controlled. This temperature difference and resulting sealing failures, increase as the packaging speed increases and also in correlation with thinner packaging materials or changing in ambient temperature. Thanks to the E5_D series, this issue is solved with the following approach: • bringing sensor closer to the sealing surface - thanks to special temperature sensor models for faster detection • adopting special algorithms (automatic filter adjustment function) built-in E5_D, specifically developed to suppress temperature variations. The result is a better sealing quality of the packages.

01:25

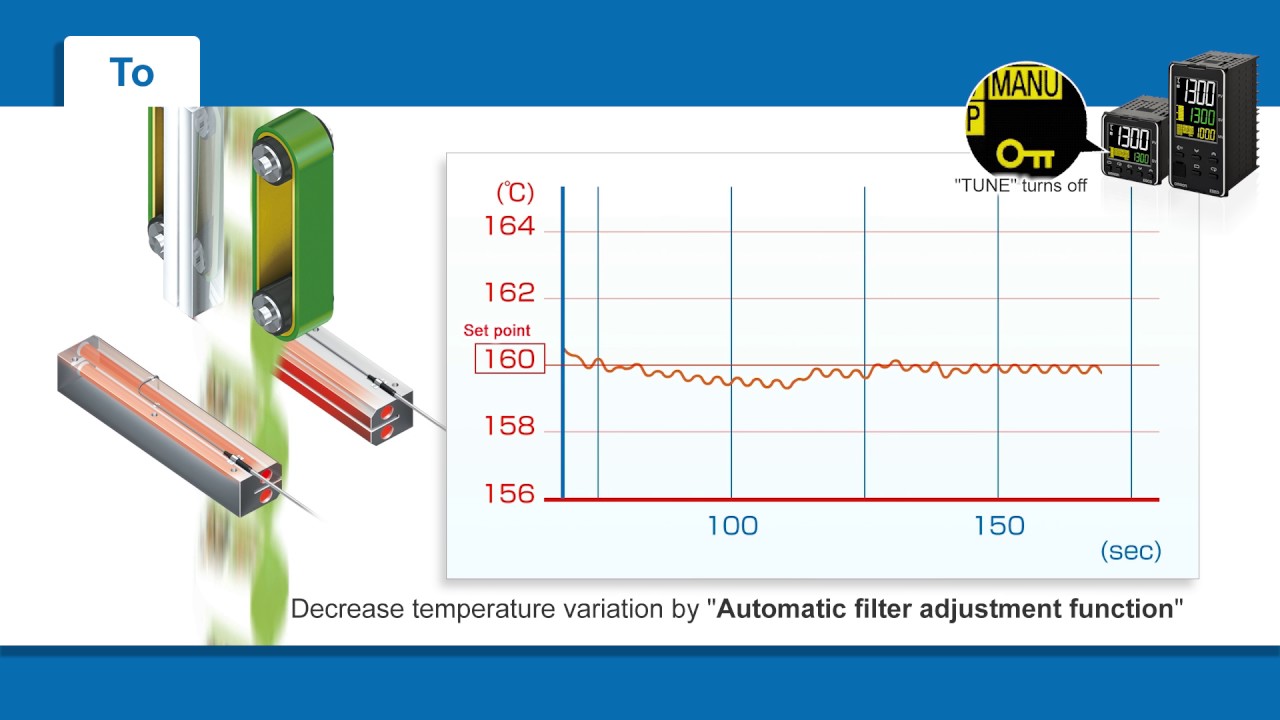

Les capteurs de température des sertisseuses classiques sont souvent trop éloignés de la surface de scellage de la barre de chauffage, ce qui crée une différence entre la température de la surface de scellage et la température réellement contrôlée. Cette différence de température et les défauts de scellage qui en résultent augmentent avec la vitesse d'emballage, mais aussi en cas d'utilisation de matériaux d'emballage très fins ou de changement de la température ambiante.

La série E5_D résout ce problème de la manière suivante :

- en rapprochant le capteur de la surface de scellage grâce à des capteurs de température spéciaux pour une détection plus rapide

-

E5_D: Perfect sealing temperature control for packaging machines (2)

On a conventional sealing machine temperature sensors can often be located too far away from the sealing surface of the heating bar. This causes a difference between the temperature of the sealing surface and the temperature that was actually being controlled. This temperature difference and resulting sealing failures, increase as the packaging speed increases and also in correlation with thinner packaging materials or changing in ambient temperature. Thanks to the E5_D series, this issue is solved with the following approach: • bringing sensor closer to the sealing surface - thanks to special temperature sensor models for faster detection • adopting special algorithms (automatic filter adjustment function) built-in E5_D, specifically developed to suppress temperature variations. The result is a better sealing quality of the packages.

01:03

- en adoptant des algorithmes spéciaux (fonction de réglage automatique du filtre) intégrés à E5_D et spécialement développés pour supprimer les variations de température et obtenir une meilleure qualité de scellage de l'emballage.

Réglage de la sortie de l'eau de refroidissement

-

E5_D TC: Temperature variations in molding machines minimized by a new algorithm

On a water-cooled extrusion molding machine, increased speed leads to temperature variations due to various factors such as the materials compounding and cooling water…For human operator that means repeatedly make valve adjustments to stabilize the quality. However It is really difficult to achieve high speed production while also maintaining the quality… With the E5_D, the water-cooling output adjustment function suppresses the temperature variations to a minimum and raises the production capacity with the quality maintained

01:33

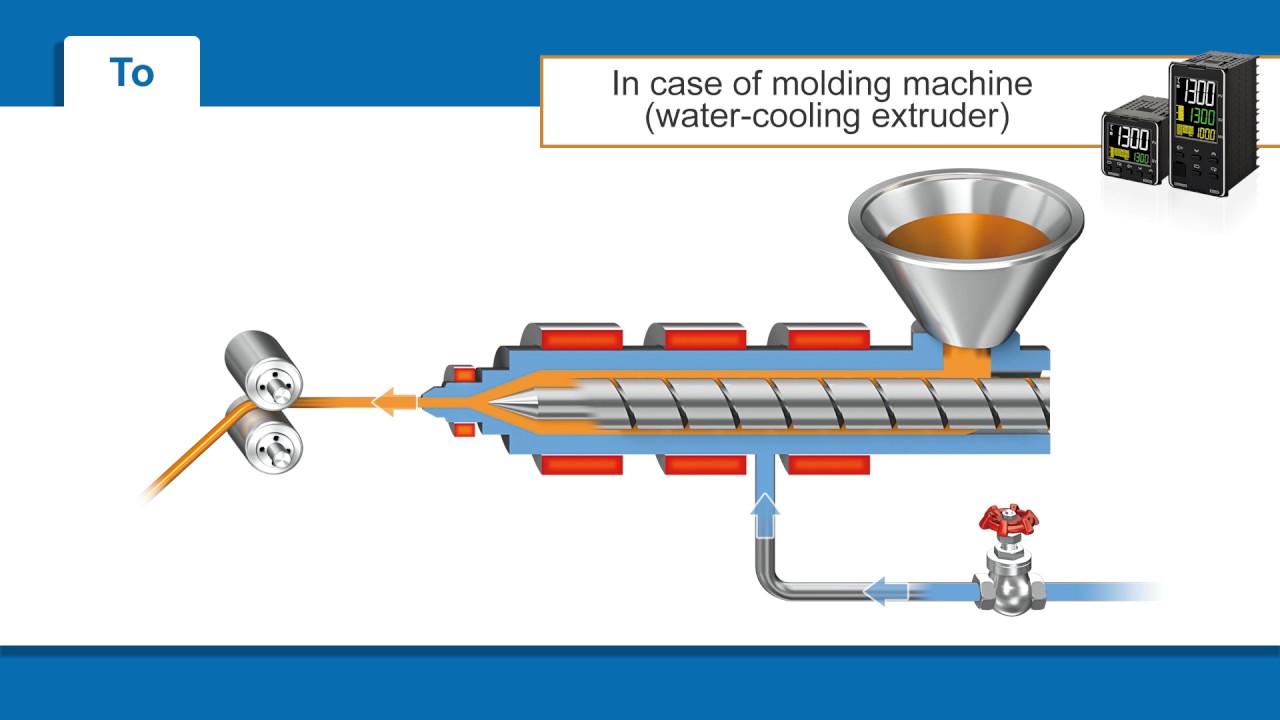

L'augmentation de la vitesse d'exécution d'une machine de moulage par extrusion refroidie par eau provoque souvent des variations de température sous l'effet de divers facteurs tels que la composition du matériau, l'eau de refroidissement, etc. L'opérateur humain doit donc procéder à des réglages de vannes répétés pour stabiliser la qualité. Or garantir de hauts rendements sans sacrifier la qualité est souvent une gageure…

La série E5_D est équipée d'une fonction de réglage de sortie de l'eau de refroidissement qui limite les variations de température au minimum et augmente la capacité de production tout en maintenant la qualité.

Téléchargements

_cg_en.jpg)

Veuillez vous connecter ou inscription pour voir ce contenu.

_cg_en.jpg)

Veuillez vous connecter ou inscription pour voir ce contenu.